Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Loading

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

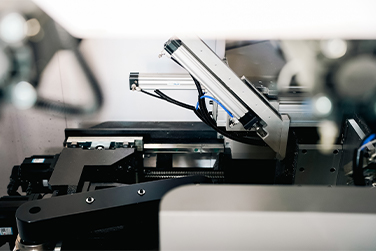

(I) High-Precision Cutting Equipment

The cutting equipment shown in the pictures is equipped with advanced saw blades and an intelligent control system. It can precisely cut 85 thermal break aluminum profiles, with the cutting error controlled within a very small range, ensuring that the profiles are joined tightly. Whether it is the profile cutting for window types such as tilt-and-turn windows and fixed sashes or meeting diverse customized requirements, it can achieve high-precision cutting, laying a foundation for the structural stability of doors and windows.

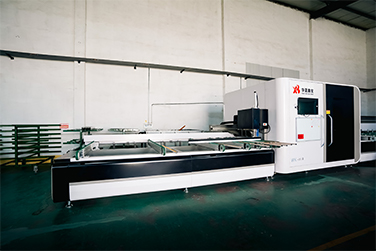

(II) Intelligent Processing Center

The large-scale processing equipment marked with “Huaxia Xinbao” integrates multi-process processing functions. From profile drilling, slot milling to fine grinding, it is completed in one stop. With digital control, it automatically recognizes processing parameters and is suitable for the processing of the complex three-cavity and three-seal structure of 85 thermal break aluminum profiles, improving production efficiency. At the same time, it ensures that each processing link is accurate and consistent, helping to create high-performance doors and windows.

(III) Automated Conveying and Assembly Equipment

The automated conveying line equipment realizes the orderly flow of profiles from cutting, processing to assembly links. Through precise mechanical transmission and positioning, it ensures the position accuracy of profiles during assembly, making the installation of hardware for tilt-and-turn windows and the splicing of fixed sashes and frames smoother, reducing errors caused by manual intervention, and improving the overall assembly quality of doors and windows.

III. Equipment Collaborative Production Process

(I) Profile Preprocessing

Use high-precision cutting equipment to accurately cut 85 thermal break aluminum profiles according to the design dimensions. The cut profiles are transferred to the intelligent processing center through the automated conveying line to complete processing such as drilling and slot milling to adapt to the functions of doors and windows, such as reserving precise installation holes for the hardware of tilt-and-turn windows.

(II) Component Assembly

The processed profiles, glass, and hardware accessories (such as imported Siegenia hardware) converge at the automated assembly station. The conveying equipment accurately positions, and workers cooperate to complete operations such as the installation of sealing strips, glass embedding, and hardware debugging, ensuring the smooth opening and closing of tilt-and-turn windows and the tight sealing of fixed sashes.

Relying on the processing accuracy of equipment and the automated process, key dimensions and processing parameters are monitored in real time during production. The finished doors and windows also need to pass equipment-assisted inspection, such as airtightness and watertightness performance simulation tests, to verify the actual effect of the three-cavity and three-seal structure of 85 thermal break aluminum profiles and ensure the quality of products leaving the factory.

(I) Quality Assurance

Advanced equipment ensures the cutting, processing, and assembly accuracy of 85 thermal break aluminum profiles, so that doors and windows have good structural stability and sealing performance, meeting high-quality requirements such as heat insulation, sound insulation, and safety, and are suitable for diverse scenarios such as residential and commercial buildings.

(II) Efficiency Improvement

The automation and intelligence of equipment shorten the production cycle and quickly respond to customized orders. From window type design to finished product delivery, it flows efficiently, helping enterprises to increase production capacity and meet market demands in a timely manner.

(III) Cost Optimization

Precise processing reduces profile waste, and the automated process reduces labor costs. The stable operation of equipment and the output of high-quality products reduce after-sales maintenance costs, achieving two-way cost optimization for enterprises and customers.

With advanced production equipment and a scientific collaborative process, Huaxia Xinbao creates a solid backing for door and window manufacturing, and empowers the construction of beautiful residential and commercial spaces with high-precision and high-quality 85 thermal break aluminum profile door and window products.