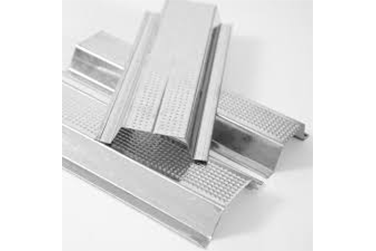

Omega-type metal groove

Omega keel plays an important role in the ceiling system, often working as a secondary keel in collaboration with the main keel. Its unique Omega-shaped design endows it with good structural stability and connection convenience. It mainly bears part of the weight of ceiling panels (such as gypsum boards, mineral wool boards, etc.) and transfers this part of the load to the main keel, which then evenly distributes it to the main building structure. Omega keels are usually installed under the main keels and are closely connected to them through supporting connectors, jointly building a stable ceiling frame structure. Because it can achieve an installation effect with no visible joints on the surface, it can create a flat appearance similar to traditional plaster ceilings, providing a good foundation for the decorative treatment of the ceiling surface, and is suitable for various decorative styles, such as modern simplicity, European classical, etc. This keel is widely used in indoor ceiling projects of buildings such as hotels, terminal buildings, bus stations, railway stations, theaters, shopping malls, office buildings, old building renovations, and various residential buildings.